Lean Manufacturing. You’ve heard about it. You probably even know someone who’s taken a corporate-sponsored course at some point in his or her career. Or, maybe you’re one of the few who view it only as an overused term in the AEC industry.

Whatever your experience with Lean, one indisputable fact holds true: companies who commit to adopting the program’s principles, experience first-hand the cost-and-time-saving benefits that ultimately result in happier customers.

The most impressive aspect of Lean Manufacturing is that the process suits a variety applications, and is not limited to only the manufacturing realm. Many refer to the practice as a lifestyle; continuously trimming the fat and eradicating forms of waste – such as extra time and material – to create a smoother operation, whether at home or work. For companies, in particular, this faster flow opens the door to speedier “in-hands” delivery when furnishing a product to customers.

From maintenance to logistics, you can put your “Lean Thinking” to to work daily and witness some major improvements almost immediately. Let’s use a fictitious.

You work in a factory assembling widgets. Each widget is comprised of three parts – the whozit, the whatnot and the thingamajig. You use a power screw gun to assemble all three parts, which takes you a total of three hours to complete. You build three widgets per each nine hour day, which makes for 15 widgets for every five-day workweek.

Your boss begins evaluating your daily process of assembly after attending a Lean/5S course. She notices that you’ve been spending a lot of time walking from one area of the shop to another, gathering your materials. She also notices that you have difficulty locating your screw gun due to lack of a functional tool organization plan. And finally, she observes that once you have your screw gun, you’re often waiting a significant amount of time for it to be repaired by the plant maintenance team.

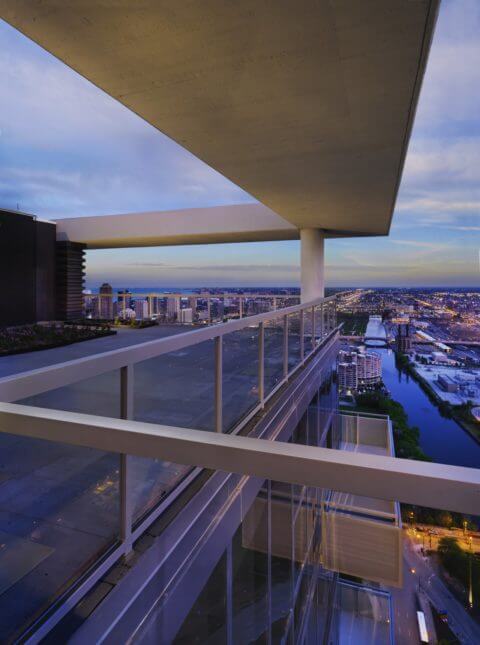

To assist in quickening your widget assembly time, your boss makes a few changes. First, she moves all three of your parts – the whozit, the whatnot and the thingamajig – closer to your workspace. Then, she creates a shadow wall for all shop tools (see photo, left, for example), so you don’t have to spend unnecessary time searching for what you need. And lastly, she makes sure your screw gun is always being properly serviced by the shop maintenance team on a regular basis to prevent tool malfunctioning and a lull in productivity.

By spending less time walking from place to place, less time looking for your tools, and less time waiting for your screw gun to be repaired, your boss determines that you’ll save about 1.5 hours per widget. With you and your team thinking “Lean”, you’ll double your production time, assembling 6 widgets per day; 30 widgets per week!

As evidenced by the hypothetical situation above, making even the smallest changes in your work processes, makes a big difference. It’s the companies who realize this, that are the most successful long-term.

To learn more about Lean Manufacturing, click here or contact the local Lean Manufacturing training team in your area.