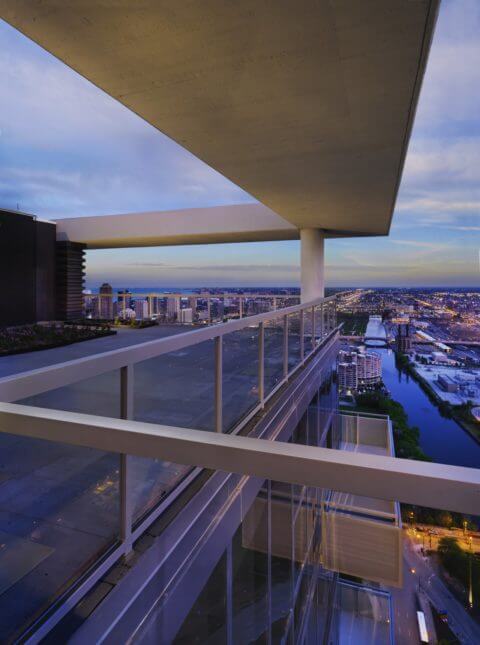

Sterling Dula Railing on Skybridge Residential Tower Chicago, IL

It’s no secret that clear communication on all sides – beginning with the building owner, followed by the architect, contractor, manufacturer and, lastly, the installer – improves the speed of a project and cuts down significantly on unnecessary costs.

Below are 3 key ways that architects and contractors can minimize change orders for architectural railing systems.

Not only will your specific railing concept expedite the quoting process, it will expedite the entire job itself.

Not only will your specific railing concept expedite the quoting process, it will expedite the entire job itself. Do you want aluminum or stainless steel components? Pickets or pipe? Wire mesh or glass infill? Is the system raked (sloped) or radiused (curved)? What’s the desired color or finish? Once these general questions are answered, the manufacturer can help you put the wheels in motion and make your design come to life.

1.Have a specific concept in mind.

Not only will your specific railing concept expedite the quoting process, it will expedite the entire job itself.

Do you want aluminum or stainless steel components? Pickets or pipe? Wire mesh or glass infill? Is the system raked (sloped) or radiused (curved)? What’s the desired color or finish?

Once these general questions are answered, the manufacturer can help you put the wheels in motion and make your design come to life.

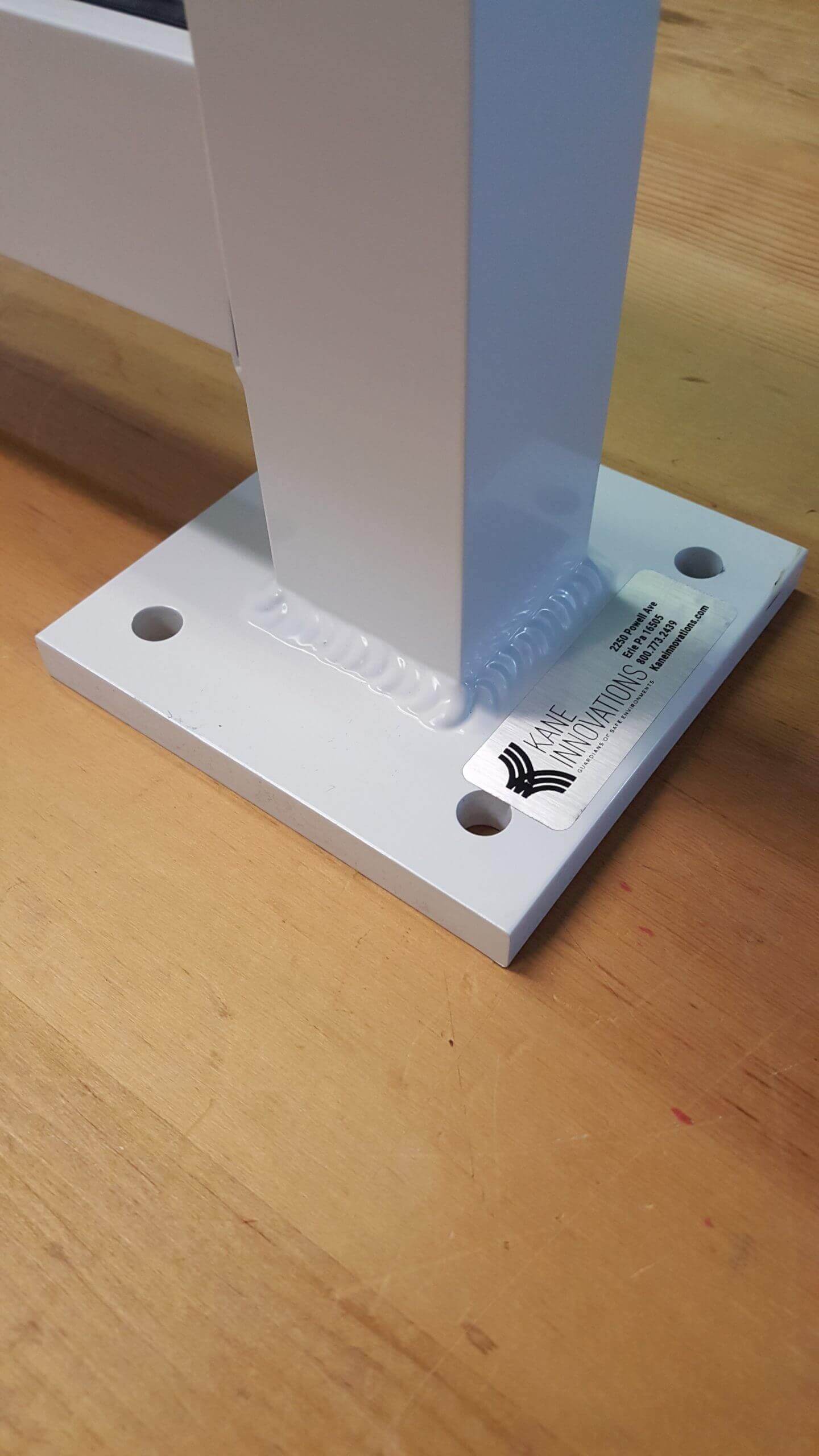

2.Know which type of surface your railing will mount to.

Is it wood, concrete, masonry or metal panel? Is this a new structure or an existing structure?

Much of the success of your railing installation will depend on having all of these details up front. That way, the railing can be designed for the appropriate mounting conditions and your customer will have railing that attaches both safely and securely.

For more info on mounting conditions, refer to our previous post entitled, 5 Important Reasons Architects, Building Owners and/or GCs Should Never Wait to Finalize a Railing System.

3.Know when you want the railing on-site.

A good rule of thumb is to know when you want the railing delivered to your job site, then work backwards according to your manufacturer’s recommended lead times. This will ensure on-time delivery and installation.

Do you want it in 3 months, 6 months, a year? Determine the dates with your team and communicate this info to your manufacturer’s representative. The time and money you will save in the long run will surely be well worth it.

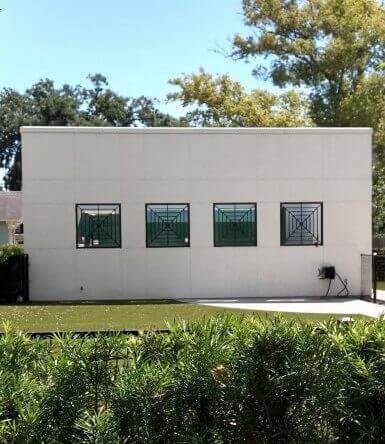

BALCONY REPAIR SOLUTIONS

- Protective coatings

- Rust inhibitors

- Switching railing mounting method from embedded to surface

- Patching/chipping away old concrete and adding new concrete

- New aluminum railing installation (when steel railings have or are corroded)

- Cathodic protection (a process which raises the pH level and lessens the acid around steel reinforcements using a low voltage electrical current)

For more information on railing systems for architectural applications, CLICK HERE.