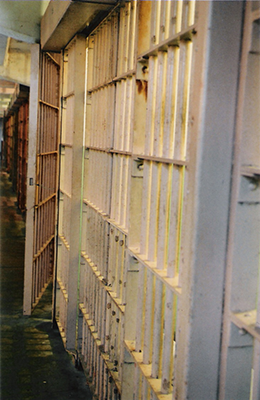

Inmate escape prevention is the number one concern of detention equipment maintenance facility personnel. No matter how vigilant a guard might be, the chances of a prisoner fleeing increase exponentially if faulty equipment is being used. This is why careful inspection of existing equipment is so important.

Below are some detention equipment maintenance tips to help you determine if your facility’s equipment is failing or about to fail. Repairing or replacing components of a system when you notice a problem can mean the difference between peace of mind for the community, and a dangerous criminal at large.

- PREVENTION – The best way to avoid a problem is to prevent one from occurring in the first place. Putting a scheduled preventative maintenance program in place – especially on high cycle doors – is imperative.

- TRAINING – Contact the locking system’s manufacturer and ask for training. Most, if not all locking system manufacturers offer training classes.

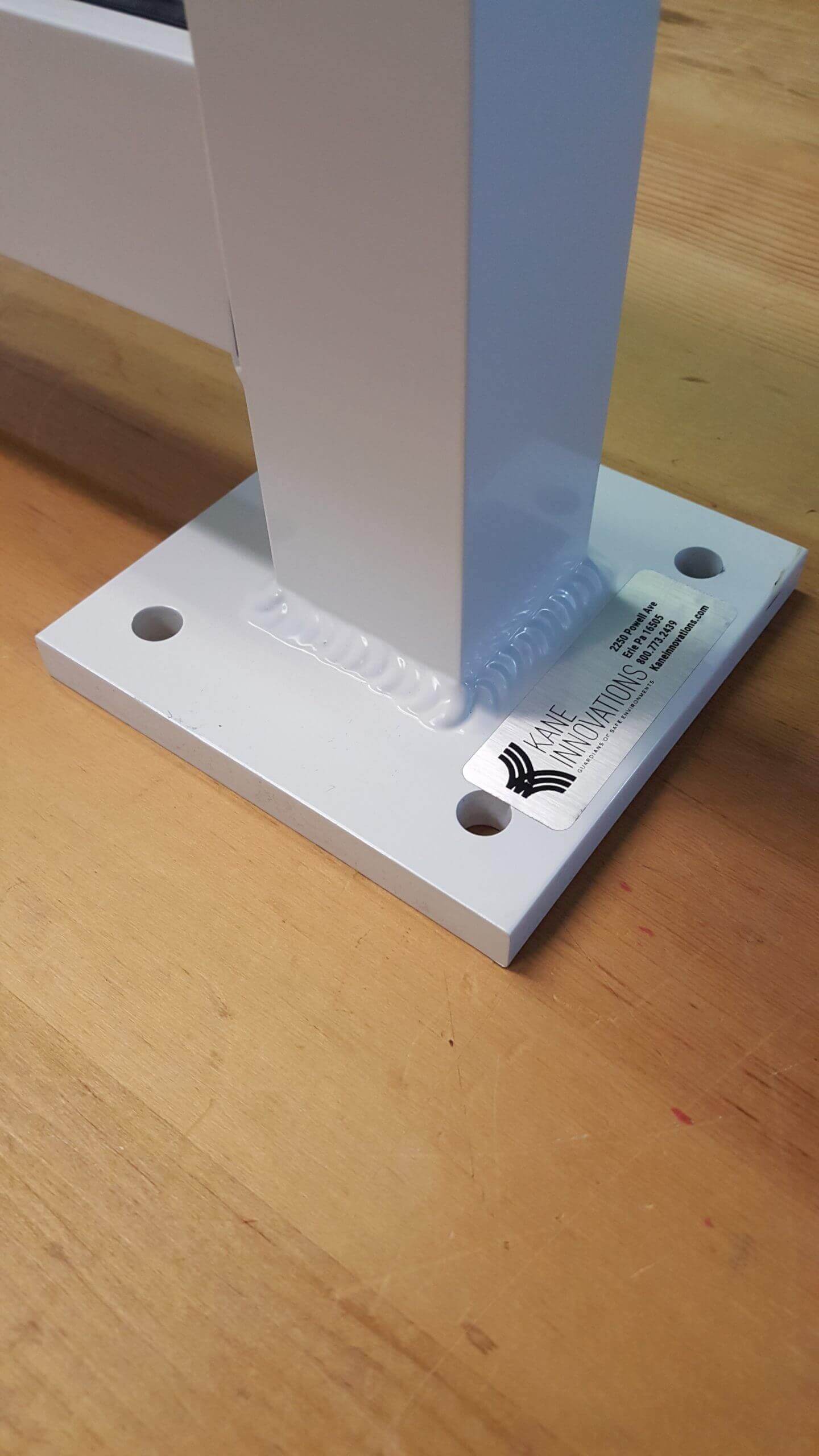

- LOCK TEST – Is the lock problem really in the lock, or does the problem lie within in the security electronics that control the lock? A “lock tester” device can answer this question quickly. With a lock tester, maintenance professionals can operate an electric lock independent of the control system to isolate and easily identify where the problem originates.

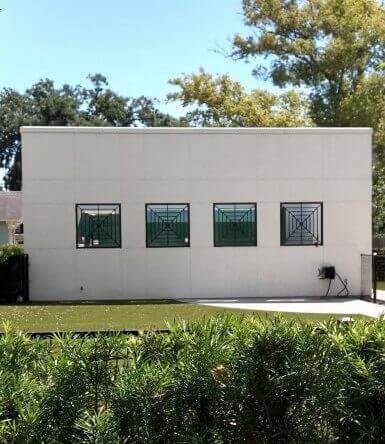

- VISUAL INSPECTION – It might seem obvious, but it’s absolutely necessary. Leaking oil or grease on the outside of housing, metal shavings on the floor, latches binding and keys that are difficult to turn in an operating lock are all signals there is a serious problem. Instruct your line staff to advise the maintenance staff when these and other physical signs are present.

To learn more about detention equipment for criminal justice facilities, CLICK HERE.