A common question asked within the architecture, engineering and construction field is:

“Why should we use aluminum railings on this project in lieu of another metal, such as steel?”

There are several reasons why aluminum is superior, for both new and retrofit projects. Below are four key facts about aluminum railings that every design-build firm, concrete restoration company and consulting engineering group needs to know:

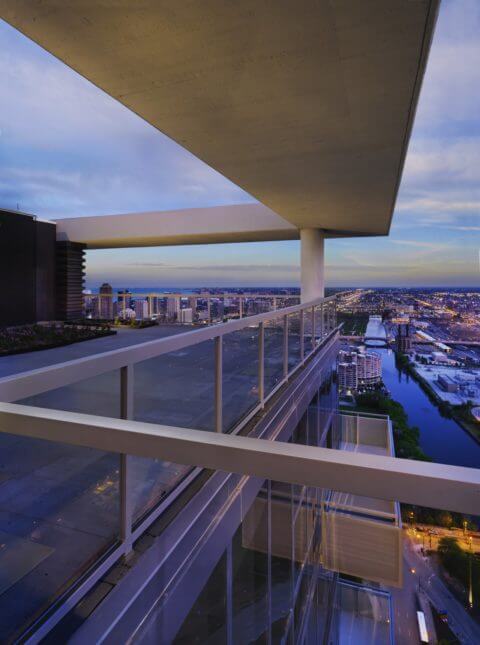

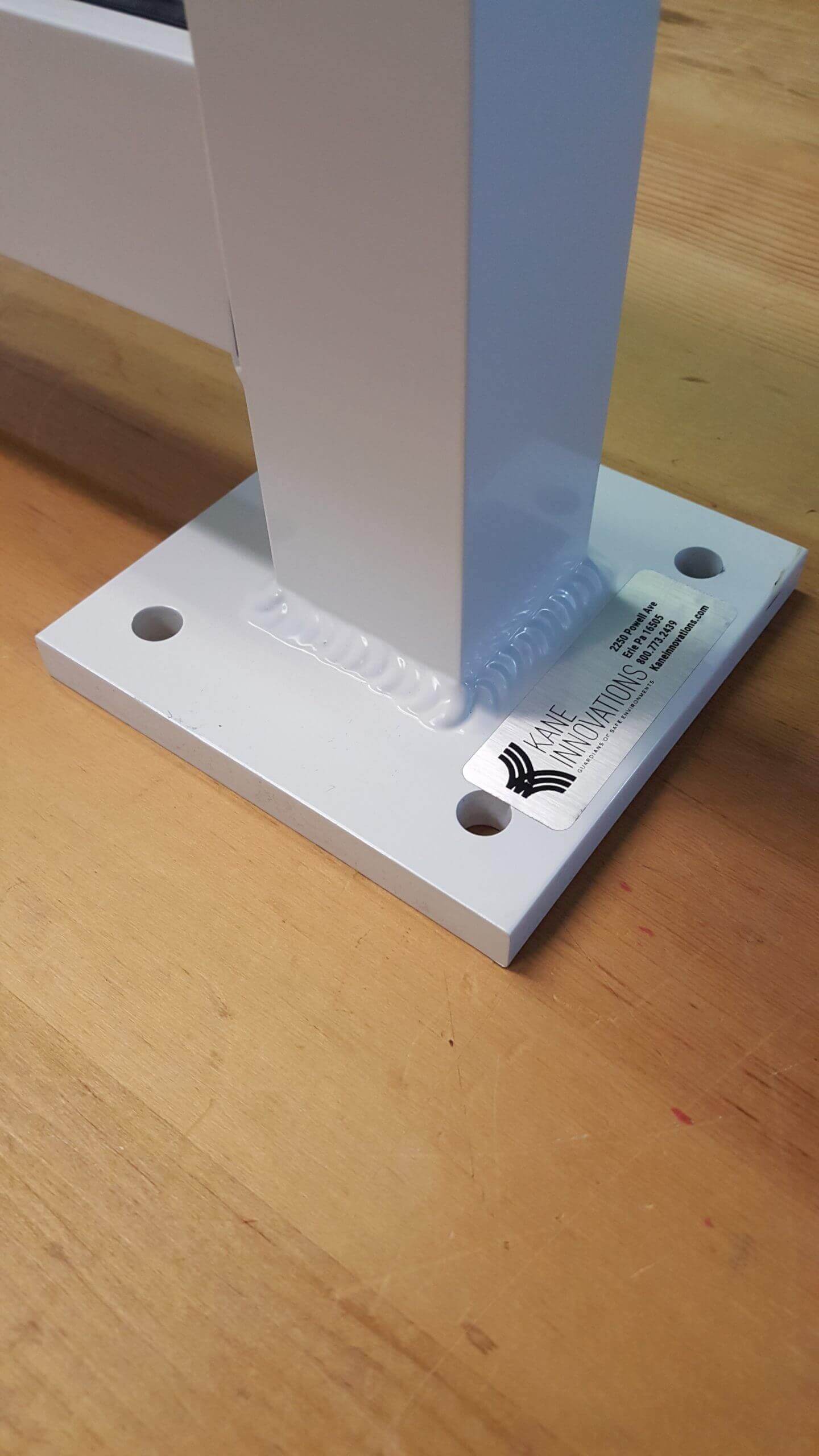

1. VERY LOW MAINTENANCE – Light cleaning is all that’s required for aluminium handrails. Aluminum is a unique metal in that it will not rust nor corrode. Pair that kind of durability with a paint finish like polyester powder coat and you’re in for decades of high performance railing.

2. LIGHT WEIGHT – Aluminum is much, much lighter than steel which gives both the designer and installer freedom in many areas of project development and construction. However, the first place you’ll notice the difference is in your budget. Since aluminum railing systems are lightweight, it’s less expensive to ship – and install.

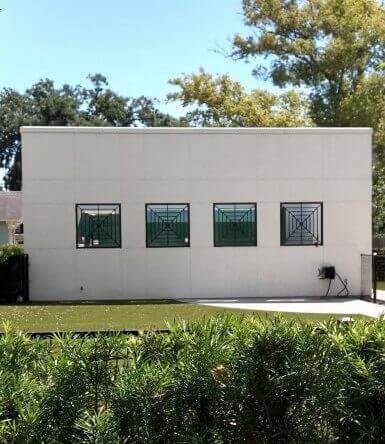

3. CUSTOM CREATIONS – Aluminum is less rigid than steel which gives the designer complete creative control. From curved rail to ornate infill panels, the sky is the limit with what an architect can create.

4. FINISHING FREEDOM – From powdercoat paint to Kynar resin, aluminum offers a full range of finish options to blend flawlessly with your completed design.

Although there are many types of metal railings that could work for your architectural creation, aluminum offers much more versatility with less headaches than other common options.