Since railing systems are usually one of the last elements added to a building during construction, timing and planning are especially crucial, as costly adjustments and delays could occur. Therefore, all trades must be on the same page.

Below are 5 railing issues architects, building owners and/or general contractors should consider and address prior to the construction of a building project.

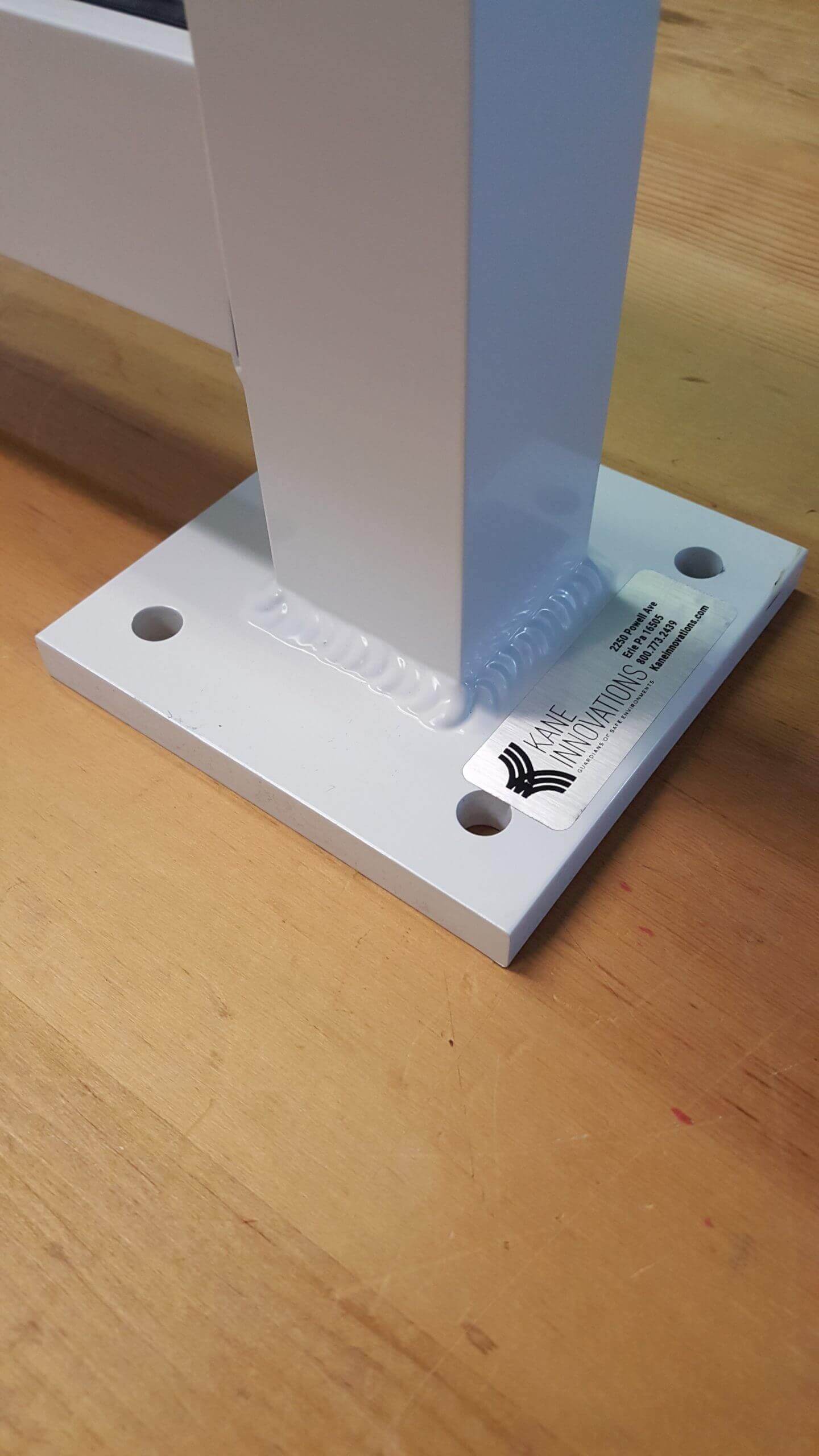

1.EMBEDDING & FOAM BLOCKOUTS

- What They Are: Embedding is the process of grouting railing posts into holes in concrete. Blockouts are used to create a void in the concrete which allows for railing posts to be embedded. Styrofoam is commonly used to prevent the wet concrete from entering the blockout. This foam is later removed from the void to make room for the post.

- What to Do: If you’re choosing a railing with embedded mounts, make sure this mounting option is communicated to (and confirmed with) those responsible for pouring the concrete.

- What Could Go Wrong if You Wait: If plans for an embedded mount aren’t communicated to the concrete contractor in time, it’s likely that foam blockouts and post holes will not be created. Drilling to create post holes after the concrete has cured could present a myriad of liability issues, not to mention eat away at budgets and create significant delays. When a situation like this arises, the most cost effective solution is to switch to a surface mounted plate. However, this too will take extra time and money to implement.

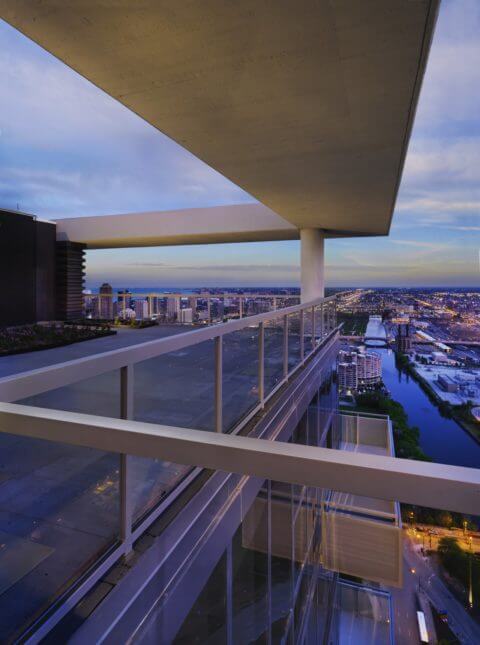

2.BASE PLATES & TENSION CABLES

- What They Are: Base plates are plates welded to the bottom of railing posts to allow for the railing to be bolted to the building structure. Post-tensioned concrete (or “PT concrete”) is composed of cables that run through the concrete and are tensioned to gain strength. PT concrete uses less structural columns than a conventionally-poured concrete deck.

- What to Do: Communicate to the railing installer exactly where the tension cables are located within the concrete slab.

- What Could Go Wrong if You Wait: Railing installers will be unable to mount the railing to the concrete slab in the appropriate places due to the tension cables being in the way. The placement of these cables can be coordinated with the help of post layout drawings provided by the the railing manufacturer, to give installers a clear space for mounting.

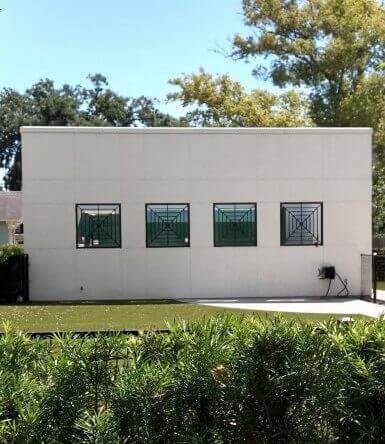

3.WALL MOUNTING & WOOD BLOCKING

- What it is: Wall mounting secures rails to the facade of a structure. Wood blocking refers to pieces of wood or other material that run between wall studs in order to provide support and attachment sites for hardware, such as railing mounts.

- What to Do: Make sure that wood blocking is completed before any drywall or facade finish (i.e. brick, cladding, etc) is applied.

- What Could Go Wrong if You Wait: If wood blocking is not completed, the railing cannot be mounted, as there is no wall anchor. The newly installed finish will have to be cut apart and later refinished after anchors are added in the correct areas. Your best option in this situation is to cut into the interior drywall to add the wood blocking.

4.BUDGETARY CONSIDERATIONS & VALUE ENGINEERING

- What it is: A budget is the funding allotted for the completion of a particular project. Value engineering (VE) preserves time, cost and quality when manufacturing a product.

- What to Do: As stated earlier, a railing system is one of the final components that will be added to a new building. Keep a close watch on your budget figure as other products and materials are installed during the earlier stages of the construction process.

- What Could Go Wrong if You Wait: It’s certainly not unheard of to be close to going over your budget by the time your selected railing system is slated for installation. If you wait to deal with railings until installation time, you could even end up in the red. Be sure that the appropriate funds are set aside for these important components and/or implement value engineering practices with help from your railing manufacturer. Most likely, you’ll have the opportunity to exercise VE options up until the product goes into production.

5.LEAD TIMES

- What They Are: A lead time is the time between the initiation and the completion of a product – such as a railing system – as it pertains to production.

- What to Do: No matter which railing manufacturer you choose, always be sure to get a firm lead time before every project, even if you’ve worked with the same company in the past. Factory schedules could vary based on workload and backlog.

- What Could Go Wrong if You Wait: If both the customer and the manufacturer aren’t on the same page with lead times, components might not be delivered on time, causing significant delays in project completion.