3 Tips for Getting it Right

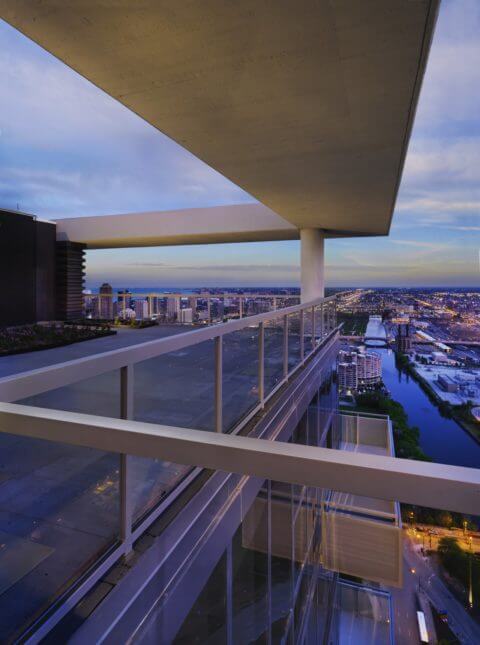

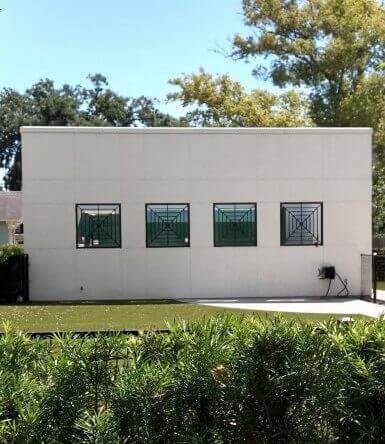

When done correctly, windscreens are as functional as they are beautiful. However, there are a few important points to remember when designing these unique systems for a rooftop terrace, pool deck, or other high-level, outdoor common area.

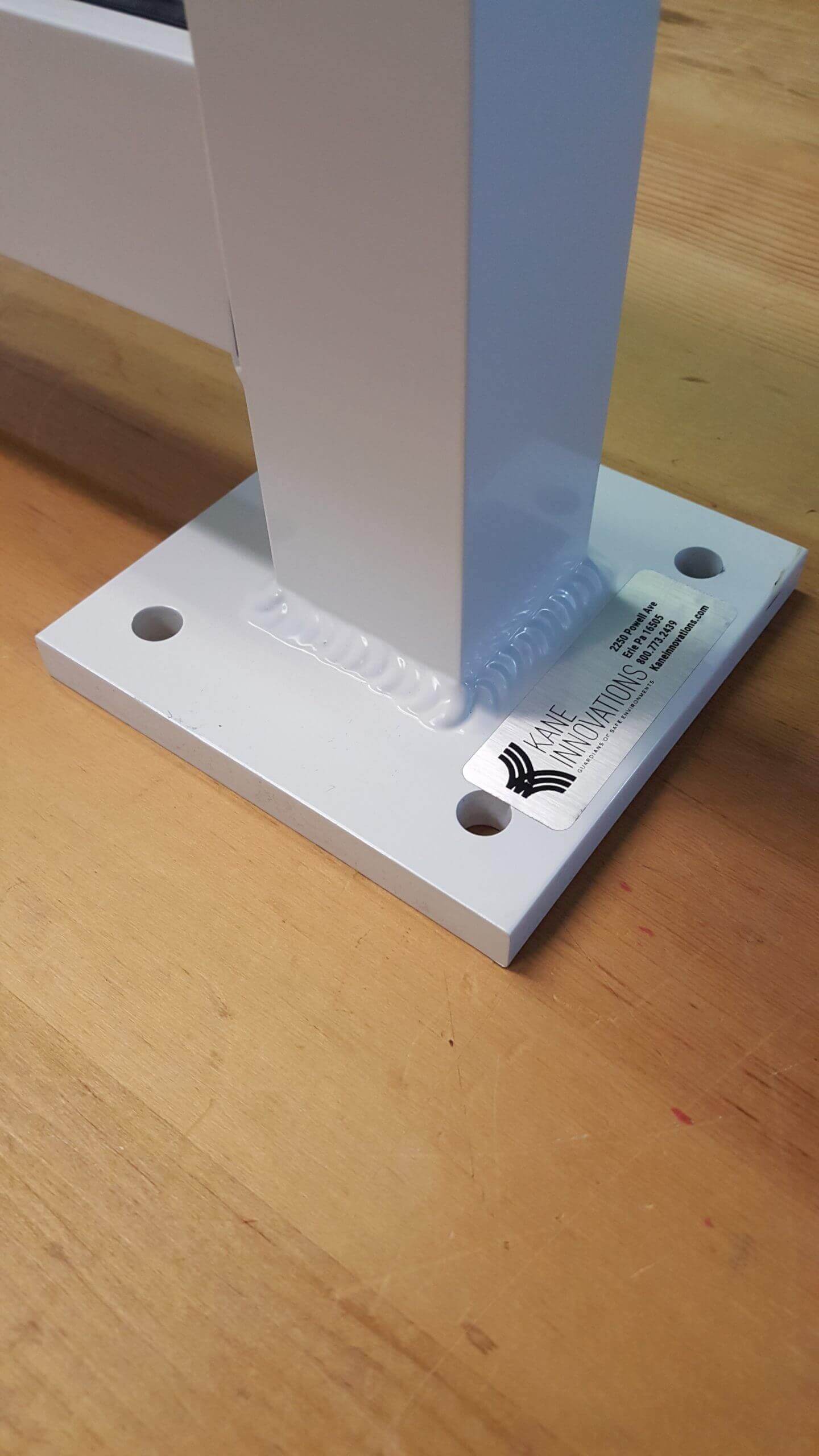

TIP #1: Mounting Conditions are Critical

Windscreens require a structural wall on which to mount. Light-gauge steel with a veneer-type finish typically will not serve as an adequate attachment base. Think of the windscreen as though it were a sail catching the wind: the force of the wind gust transfers to the wall, thereby requiring the wall to be strong enough to withstand this impact. Where wind loading is a concern, an appropriate mounting surface is imperative to the safety of the system.

TIP #2: Remember Taller is Better

Windscreens will not perform well at the IBC standard height for railings, which is 42″ tall, or 3-1/2 feet. Although the overall height will vary by application, Kane Innovations recommends that windscreens begin at four feet, with the tallest average height reaching eight feet. Any system exceeding eight feet will require additional structural components to ensure stability.

Taller windscreens directly increase the usability of the space – in many cases by months – by curtailing wind gusts. Even in northern climates, outdoor areas are protected by a 72″ or greater windscreen can have virtual year-round use of many amenities.

TIP #3: Early Involvement Yields the Best Results

Expert railing manufacturers like Kane Innovations will always create a constructible product that anchors well with your substrate, while taking the time to work out all design challenges up front to fulfill the desired aesthetic and code requirements. However, because this process is so involved, sooner is always better. Turnkey manufacturers work hard behind the scenes to ensure that each system gets built and installed exactly how it was intended which makes an adequate allowance of time a vital piece of the process.

The key to windscreen design is remembering that the wind that would otherwise gust across the amenity area, is now creating a load on the entire system. In other words, all of the wind that would be blowing into the space is now pushing with full intensity on the glass barriers. Therefore, finding balance between sight lines, visibility and, most importantly – structural integrity – is crucial to the success of the installation. It’s equally as important to work closely with other trades to ensure adequate waterproofing and adherence to all local and national building codes.

Up front knowledge of these important windscreen design basics will not only promote a smoother overall experience for construction teams, it will create a much safer, more enjoyable environment for the end user.