Expedited Delivery and Installation Achievable Despite Exponential Increase in Sales Volume

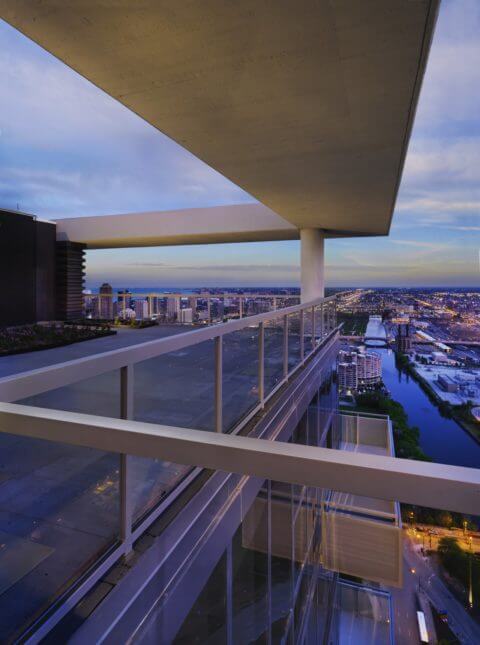

ERIE, Pennsylvania – October 7, 2016 – Kane Innovations is setting a new industry standard this quarter with some of the fastest railing lead times currently available from an architectural building products manufacturer.

Thanks to an improved process flow, Kane Innovations has not only exceeded sales goals for the first part of their new fiscal year, they’re now offering accelerated lead times to Sterling Dula railing customers, upon request. (Related: KICK OFF: Kane Innovations to Complete Texas Railing Project in Time for Superbowl LI)

Kane Innovations President Michael Show said that although the uptick in sales volume and shortened lead times may appear fortuitous from an outside perspective, Kane Innovations’ current success is anything but accidental.

“We’ve worked with intention to get to this point,” Show said. “Our success is the result of a powerful plan that we put in place months ago to reach our goals. It’s about getting people focused on all of the right things, establishing metrics, and providing constant feedback on ‘actual versus target’.”

Show said that due to these streamlined processes, railing can be produced weeks ahead of schedule for a customer who needs it delivered to the job site, or installed quickly. Typical railing lead times hover around the eight week mark.

“We are able to accomplish in days, what it takes our competitors weeks or months to complete.

“The key to our process,” said Show, “is that we start asking customers early, ‘When do you need your railing?’ and we set our schedule based on the specific date they provide. It’s amazing what our team of professionals can accomplish when given a deadline.”

Show said that these new lead times can be attributed to recent modifications within three major departments: engineering, project management and production.

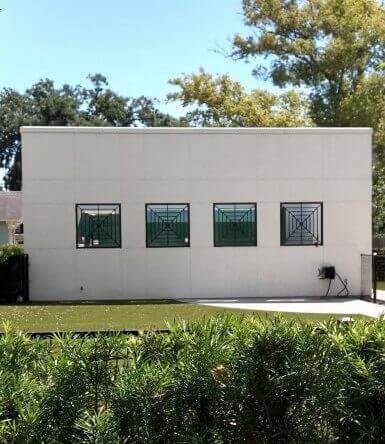

“In engineering, jobs are being processed quicker with help from software that reduces rework. Plus, the department is staffed sufficiently to handle quick turnaround times and increased sales volumes,” said Show. “In project management, remote Project Managers (PMs) are on-site more often, allowing them to react immediately, should any problems arise.”

Show also explained that Kane Innovations’ new, state-of-the-art surveying techniques are producing more accurate and timely field measurements, which adds to the company’s success.

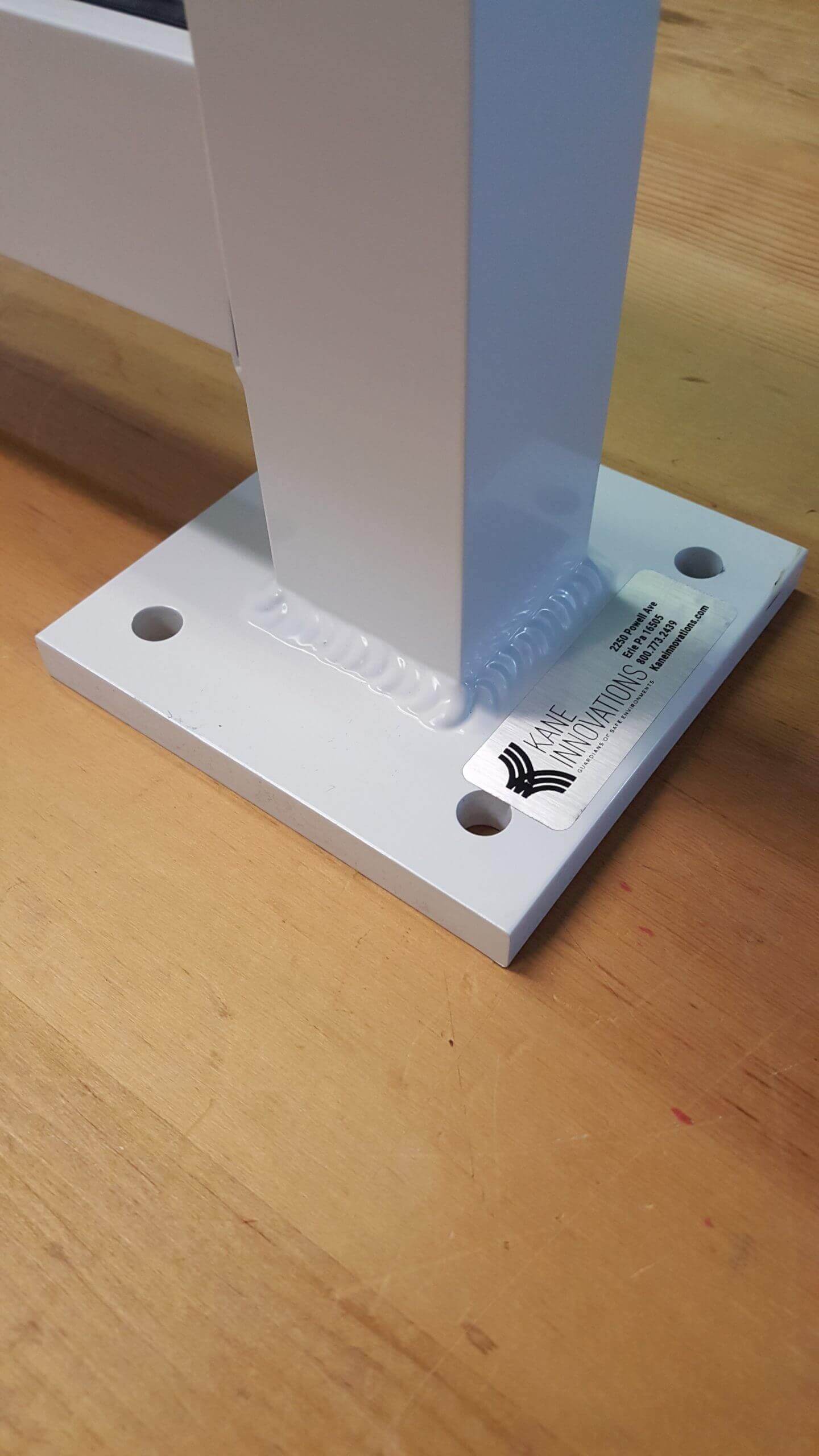

When asked about production improvements, Show said that the newly implemented layout at the Erie plant has improved fabrication practices immensely.

“Our new Lean layout in Erie was implemented over the past year, which has made a huge difference for us. Parts are now processed through the shop in a continuous flow – in lieu of traditional batch processing – while production and efficiency are monitored simultaneously. Layout improvements have also been made at our secondary plant in Kane, and we’ve set up an incentive plan to reward workers at both locations,” he said.

Procedure optimization is just one example of how Kane Innovations has been effective in remaining competitive since the company was founded in 1890. The president of Kane Innovations believes that staying true to the company’s philosophy is what has made all the difference over the last 126 years.

“Through the years, we’ve learned how to adjust our sails in changing winds, and keep moving forward,” said Show. “Our flexibility, resilience and willingness to try new things is what keeps us ahead of the curve.

“Our goal has always been continuous improvement.”